Customized and Reliable Stepper Motors Address HVAC Damper Application Extremes

If you have to regulate HVAC system airflow on a constant basis, you’ll need automatic dampers with electric or pneumatic motors that can be controlled by a thermostat or building automation system. When designing an external mount electric damper actuator for an HVAC system, it’s important to review considerations in order to create the best motor-damper combination.

When evaluating a miniature motor to pair with an actuator, keep in mind that it may need to be customized. Ask yourself the following questions:

- How much torque and force must the motor-linear actuator combination deliver to hold the damper in position with the required control precision?

- Can the motor withstand temperature extremes?

- Can the motor components be customized to withstand HVAC cycles?

- Does the motor offer the position feedback required by the integrated damper?

Rotor Design Is Critical

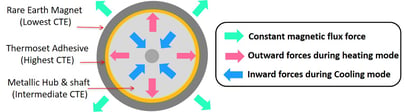

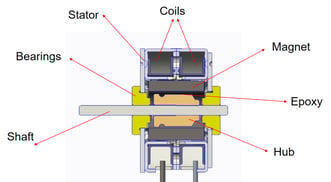

For custom motors used with damper actuators in HVAC applications, rotor design is critical. Within the damper actuator, the motor will start and stop under varying thermal conditions, putting additional thermo-mechanical stress on the rotor and other internal components. The nonlinear material used in rotors must have certain thermal properties to operate reliably in extreme temperatures. Choosing linear and nonlinear material-based assemblies can be challenging because the performance of nonlinear materials, like adhesives, depends on material chemistry and processing parameters. Certain ceramic magnet grades make the decision even more difficult.

Design Validation Through Qualification Testing

While the material scheme you choose considers performance under static environmental conditions, dynamic conditions may involve rapid temperature, humidity or sudden load changes, or combinations of multiple factors. The scheme also must be validated to determine the motor’s long-term performance via simulations or analytical testing. Validation should include:

- Testing rotor assemblies at accelerated temperatures and thermal shock conditions in environmental chambers and ovens

- Axial and torsion force tests to determine rotor mechanical strength at a specific temperature requirement

- Accelerated life testing to predict a motor’s service life in its application.

Be sure to test under loaded and unloaded conditions, depending on the application requirement.

Custom, Reliable Stepper Motors Can Suit Your Needs

Stepper motors represent a good technology choice for use in electrically operated dampers. They are more affordable than brushless DC motors, and typical damper applications do not need the latter's superior variable speed capability.

The right stepper motor is critical to efficient airflow control in HVAC systems. That’s why you’ll need to choose from a wide variety of stepper motors with different configurations. Stepper motors offer the HVAC actuator market an attractive price-to-performance ratio, and Portescap provides custom stepper motors to ensure you meet your needs. Remember to bring your application requirements to your stepper motor partner so they can help you address them during the critical design and validation stages.

For more information about motor selection for HVAC gas valve actuators, read the complete white paper or contact an engineer.